Principle

By lowering the pressure, the partial pressure of the dissolved gases are reduced so that they are released from the solution.

By lowering the pressure, the partial pressure of the dissolved gases are reduced so that they are released from the solution.

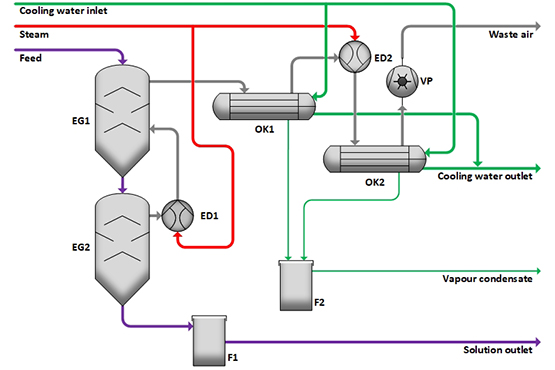

In a single-stage vacuum degassing system, the solution is sprayed in a vacuum tank EG1, where air and other gases are expelled to a great extent. If required, the first stage EG1 can be followed by a second stage EG2 in which further water evaporates and the solution is further degassed. The water steam acts as a carrier gas and improves degassing to achieve optimum results. The gases are sucked off by means of steam jet pumps ED1 and ED2 and water steam is condensed to a great extent in surface condensers OK1 and OK2 before the gases are compressed to atmospheric pressure by means of a vacuum pump VP.