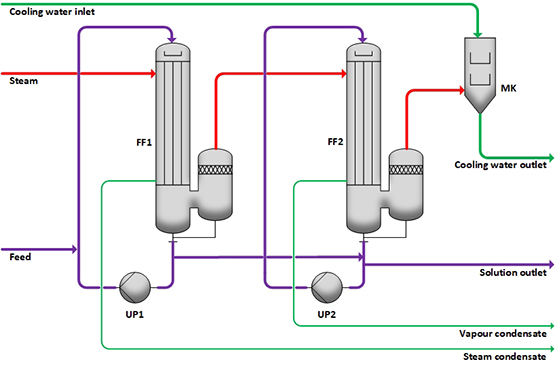

Process description – Example parallel flow principle

In the example shown, the solution is fed into the circulation line of the first stage and mixes with the circulating solution. In the evaporator tubes it is partially evaporated by steam. In the lower section of the evaporator FF1 and in the following separator, the liquid is separated from the vapour steam. The vapour steam flows to the second stage, which is operated under reduced pressure and serves as heating medium. The vapour generated in the second stage is finally condensed with cooling water in the mixing condenser MK.