Mixing Condensers and Direct Contact Condensers

Mixing condensers are efficient heat exchange systems that condense steam through direct contact with a cold liquid. These devices are crucial for processes where rapid and effective condensation is necessary.

Operation and Principle of Mixing Condensers

Mixing condensers are devices where generated steam (exhaust steam) is condensed by direct contact (“mixing”) with a cold liquid, typically cooling or chilled water or solutions. Mixing condensers usually operate under vacuum.

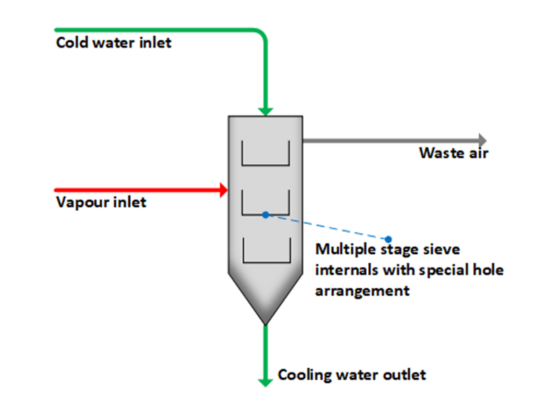

The cold liquid required for condensation is always introduced at the top of the device and dispersed into fine droplets by high-performance sieve trays. This creates a large surface area where the vapor can condense effectively.

The vapor is introduced at the bottom of the device. It flows against the descending droplets of liquid and is increasingly condensed. At the top, only the non-condensable inert gases remain, which are then diverted out of the device.

The downward-falling liquid, mixed with the condensate, flows out of the bottom of the apparatus by gravity. In multi-stage devices, this liquid can be reused for condensation.

EBNER custom computes and designs mixing condensers for each application.

Advantages of Mixing Condensers

- Cost-effective compared to surface condensers

- Efficient condensation through direct contact

- Optimized surface for maximum heat exchange

- Can be used under vacuum conditions

- Adaptable for various industrial applications

Applications of Mixing Condensers

- Chemical industry: Condensation of solvent vapors

- Food processing: Recovery of flavors

- Power plants: Condensation of turbine exhaust steam

- Pharmaceutical industry: Condensation in distillation processes

- Paper industry: Steam recovery from drying processes

Frequently Asked Questions

What are mixing condensers?

Mixing condensers are devices that condense steam by direct contact with a cold liquid to enable efficient heat transfer.

How do mixing condensers work?

They operate by distributing a cold liquid over high-performance sieves to create a maximum surface area where the steam condenses as it rises and meets the falling droplets.

Can mixing condensers operate under vacuum?

Yes, mixing condensers are designed to work efficiently even under vacuum conditions.

In which industries are mixing condensers used?

Mixing condensers are used in the chemical, food, power, pharmaceutical, and paper industries, among others, for the condensation of vapors and solvents.

What is the advantage of mixing condensers over other condensation systems?

Their main advantage is direct condensation, which allows for efficient heat exchange and low energy consumption, especially in processes that require rapid condensation.