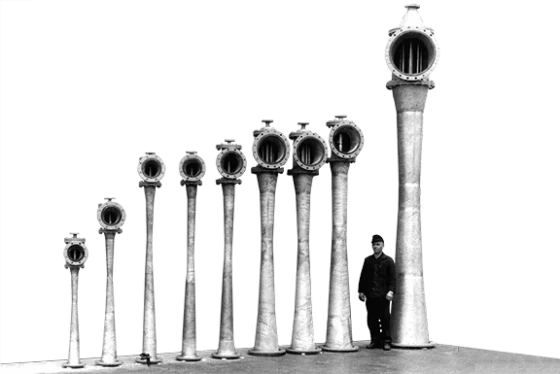

Steam Jet Pumps and Venturi Pumps

Steam ejectors, also known as eductor pumps or venturi pumps, represent an efficient solution for the transport and compression of media using steam power.

Steam jet devices can be used both for creating a vacuum and for thermal vapor compression. They draw in fresh steam, exhaust steam, or other gases at low pressure and compress them to a higher pressure. They consist essentially of three parts:

- The motive nozzle

- A mixing chamber

- A venturi-shaped diffuser

Water steam is normally used as the driving fluid. However, other vapors or gases can also be used. Each steam jet device is designed for specific conditions and can therefore only overcome a certain pressure gradient.

For larger pressure differences, several steam jet devices are connected in series, and in the case of vacuum generation, condensers are placed between the steam jet devices to condense the motive steam from the upstream steam jet device.

EBNER manufactures steam jet devices for use in its own plants, as well as according to customer requirements.

Advantages of Steam Ejectors and Eductor Pumps

- Simple design with no moving parts, leading to high operational reliability

- Low wear and maintenance

- Corrosion-resistant with appropriate material selection from all materials usable in apparatus construction

Applications of Steam Ejectors and Eductor Pumps

- Process technology: Efficient vapor compression and vacuum generation.

- Environmental technology: Transport of gases and vapors in cleaning processes.

- Energy industry: Optimization of condensation processes.

- Food technology: Vacuum packaging and processing for shelf-life extension.

Frequently Asked Questions

What advantages do venturi pumps offer in industrial applications?

Venturi pumps are robust, require low maintenance, and can be adapted for a variety of media.

Are Venturi pumps suitable for all types of gases?

Venturi pumps are versatile, but gas properties must be considered in the design.

Can steam jet devices be used in explosive areas?

Yes, due to the absence of electrical components and moving parts, they are particularly suitable for such areas.

How does the efficiency of steam ejectors vary with operating conditions?

Steam ejectors can be designed for different operating states to optimize efficiency.