Table Salt from Brine

EBNER was awarded a contract by a saltworks in Austria for the planning, delivery, and erection of a plant for the extraction of high-purity table salt (NaCl) from brine through a combined and patented circuit of evaporation and cooling crystallization, which is characterized by particularly high economic efficiency.

- Region: Austria

- Type of Plant: Evaporation Crystallization with Mechanical Vapor Recompression

- Services: Engineering, Manufacturing, Erection, Commissioning

Optimized Salt Production: NaCl Crystallization with Energy Saving

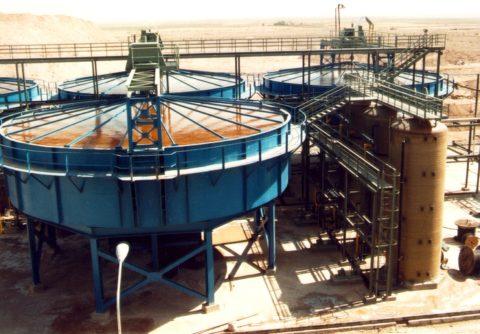

EBNER developed a process specifically tailored to the saltworks. The brine is initially extracted through cavern mining and pre-cleaned in a brine purification stage. The evaporation plant operates with mechanical vapor recompression (turbo-compression), meaning electrical energy is used for evaporation instead of steam energy.

The produced NaCl salt is separated. The remaining saturated hot mother liquor is partially depressurized in a downstream multi-effect plant, partly under vacuum, which further crystallizes additional NaCl salt. The vapor generated in the stages by decompression heats each subsequent stage and provides additional evaporation without the use of additional heating energy, thereby saving energy. The produced salt is separated and, along with the salt generated in the evaporator plant, fed into the drying, packaging, and storage system.

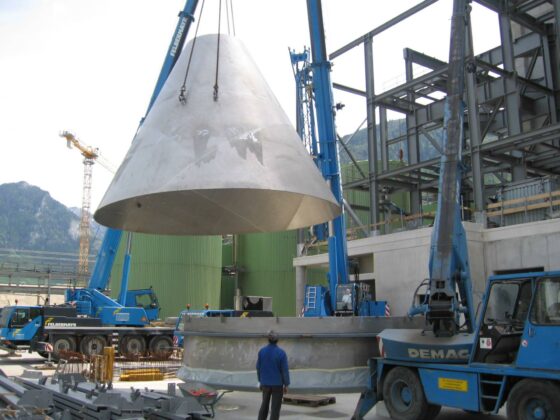

EBNER Masters Complex Erection: Prefabrication and Erection of an Evaporator

In this project, EBNER was able to demonstrate its expertise in complex on-site erections. The crystallizer with a diameter of over 6m was prefabricated in pieces in the in-house fabrication and assembled on-site at the customer’s premises. A major challenge was the high-quality material and the associated complex welding work, including post-treatment.

EBNER was awarded this contract not only because of the much higher economic efficiency compared to the competition but also because of the good experiences with EBNER based on a previously completed project to the customer’s fullest satisfaction

Technical Data of the Plant

- Feed rate of solution: 180 m³/h

- Main components of the solution: NaCl, KCl, Na₂SO₄

- Water evaporation: 150 t/h

- Product: NaCl

- Production volume: 50 t/h

Scope of Services of the Project

EBNER’s “turn-key” scope of supply with company personnel included, among others:

- Basic and detail engineering incl. design of main components

- Manufacturing of main components after in-house prefabrication

- Erection of the entire plant incl. steel construction

- Commissioning of the entire plant

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References