Crystallization of Li₂CO₃

In addition to other salts, also lithium carbonate (Li₂CO₃) is essential for the battery industry. Lithium carbonate salts are used in the battery production in the highly pure “Battery Grade” form.

In the production of lithium carbonate (Li₂CO₃), there are various process routes, such as:

- Conversion of dissolved lithium sulfate or lithium chloride by adding sodium carbonate into lithium carbonate (Li₂CO₃) followed by the precipitation of lithium carbonate (Li₂CO₃).

- Evaporation from lithium carbonate solutions and crystallization of Li₂CO₃ in evaporation crystallization plants.

Especially in the first step of conversion with sodium carbonate, depending on the process route, by-products such as sodium chloride or sodium sulfate are produced, which can then be obtained in evaporation-crystallization plants.

In the conversion from lithium sulfate, a sodium sulfate solution is produced, which can be crystallized to sodium sulfate or Glauber’s salt in evaporation-crystallization or cooling crystallization plants, depending on the desired process.

The method according to the second step, directly from the solution, is mainly carried out in battery recycling. Here, depending on the applied process, lithium carbonate (Li₂CO₃) solutions are produced, which are first concentrated. After the possible removal of impurities, the solution is then evaporated in evaporation crystallization plants beyond the saturation limit and crystallized.

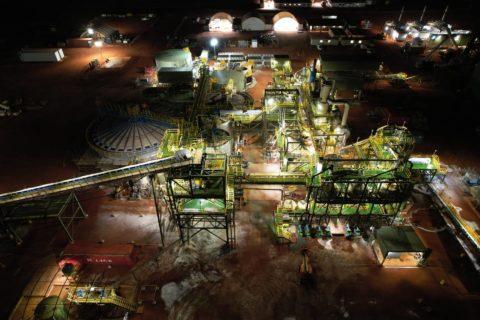

EBNER – your competent partner in plant engineering

With many years of experience in various industries and with different solutions, EBNER is your contact for optimally executing process design, planning, delivery, and erection according to your specific needs.

Frequently Asked Questions

What are the differences in the crystallization of Li₂CO₃ for “Technical Grade” and “Battery Grade”?

The difference between “Technical Grade” and “Battery Grade” lies in the purity of the sodium carbonate.

In industrial practice, recrystallization has proven useful for obtaining “Battery Grade”. Here, the Li₂CO₃ crystallized in a first step is redissolved and then recrystallized in a second step. This process typically reduces the impurities of the salt sufficiently to produce “Battery Grade” salt.

What are the peculiarities in processing lithium carbonate compared to other salts?

The main difference in processing is the very low saturation of lithium carbonate in the solution.

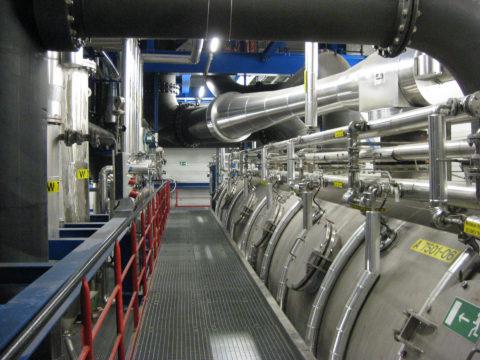

This affects the design of evaporation-crystallization plants for Li₂CO₃, requiring high specific evaporation performances (amounts of water/kg crystalline Li₂CO₃) to be evaporated. This results in high specific energy consumption concerning the produced unit of Li₂CO₃.

Also, it is essential to ensure that the apparatus of the plant is optimally designed to avoid build-ups on the walls of the plant and the need for frequent flushing requirements.

What processes can be used for the evaporation crystallization of Li₂CO₃?

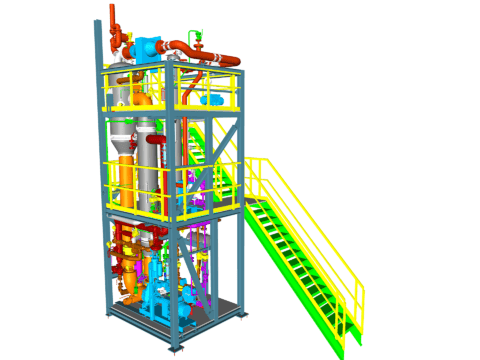

In principle, the common plant types for evaporation crystallization can be used for Li₂CO₃. These are:

- Plants for evaporation and crystallization using mechanical vapor recompression.

- Plants for evaporation and crystallization using thermal vapor recompression.

- Plants heated with fresh steam in a multi-effect configuration for the evaporation crystallization of (Li₂CO₃).

Other Applications