Crystallization of Na₂CO₃ or Soda

Crystallization plants for sodium carbonate are executed in various ways depending on the desired end product. This can either be:

- A plant for the production of anhydrous soda (Na₂CO₃) at high temperatures in the context of evaporation crystallization ,

- A plant for the production of sodium carbonate monohydrate (Na₂CO₃H₂O) through evaporation crystallization or cooling crystallization at medium temperatures, or

- A crystallization plant for sodium carbonate decahydrate (Na₂CO₃10H₂O) at low temperatures in the context of cooling crystallization.

The theoretical further possibility of producing sodium carbonate with 7H₂O (Heptahydrate) is not carried out in industrial practice due to the narrow temperature range for crystallization.

The following descriptions refer to solutions with low proportions of other components.

For example, if – as is sometimes common in industrial practice – components like NaOH are dissolved in the solution, corresponding hydrate stages will form at different temperatures.

Crystallization Plant for Anhydrous Sodium Carbonate (Na₂CO₃)

Crystallization plants for Na₂CO₃ without crystal water must operate at high temperatures, as otherwise, the crystal will form as a hydrate.

Temperatures of over 105°C are usually necessary depending on the components in the solution.

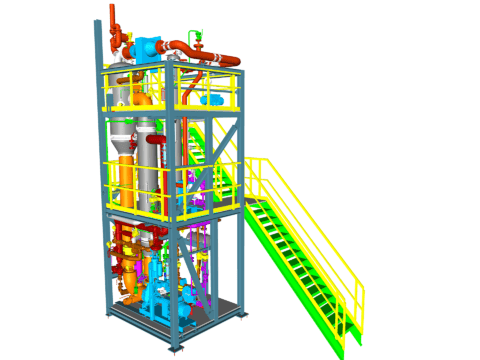

Due to the moderate boiling point elevation of the sodium carbonate solution, the following crystallization methods are possible:

- Multi-effect plant with fresh steam heating, executed in countercurrent

- Mechanical Vapor Recompression

- Thermal vapor recompression

The end product, also known as calcined soda, can then be separated in crystalline form from the plant.

Crystallization Plants for Sodium Carbonate Monohydrate (Na₂CO₃ H₂O)

To crystallize sodium carbonate monohydrate, it is necessary to remain within the corresponding temperature ranges.

Depending on the other components of the solution, a temperature range of approximately 35°C – 105°C is targeted.

Due to this wide range, plants for the production of Na₂CO₃·H₂O can be executed as:

- Multi-effect plants in co-current or countercurrent,

- Plants with mechanical vapor recompression,

- Plants with thermal vapor recompression.

Crystallization Plants for Soda (Na₂CO₃·10H₂O)

To produce sodium carbonate decahydrate, also known as soda, it is necessary to stay below the transformation temperature to the next smaller hydrate in the corresponding solubility diagram.

Here, temperatures below 35°C are targeted, so the possibilities of evaporation crystallization are not applicable.

Normally, Na₂CO₃·10H₂O is crystallized from process solutions. Vacuum cooling crystallization plants are used, where the vapor generated by flashing is condensed, for example, by cooling water or refrigerants (refrigeration plants) or by acids or bases in surface condensers or mixed condensers.

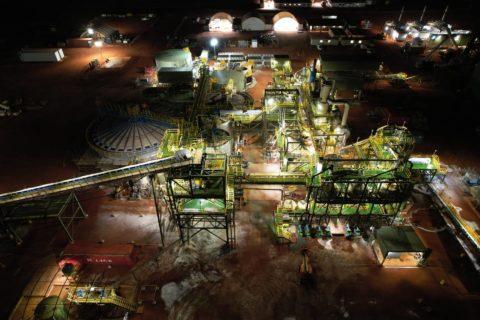

EBNER – your competent partner in plant engineering

Due to many years of experience in various industrial sectors and with various solutions, EBNER is your contact for optimally executing the process design, planning, delivery, and erection according to your needs.

Frequently Asked Questions

Is it possible to produce a different hydration state out of soda?

Just as with evaporation plants for spin bath and crystallization of Na₂SO₄, it is possible to heat the soda above the transformation point and melt it in its own crystal water. The liquid water is then evaporated in an evaporation plant.

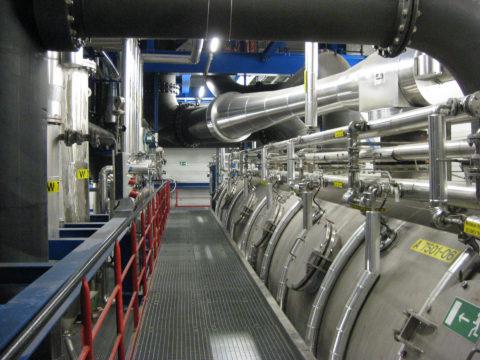

What materials are used for the apparatus of the plant?

Since the pure Na₂CO₃ solution itself does not have a significant corrosion potential, normal stainless steel can be used for heat exchangers and other apparatus.

Other Applications