Crystallizers

EBNER is a leader in the design and manufacturing of crystallizers used in demanding industrial processes. Our crystallizers are specifically designed to enable optimal crystal formation and growth, thereby achieving high purities and the desired physical properties of the crystals.

Types of Crystallizers

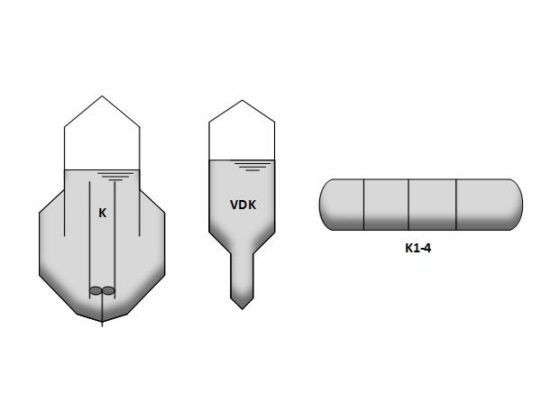

- Draft tube baffle crystallizers with bottom flange mixer and clarifying ring (Draft Tube Baffle, DTB).

- Vertical crystallizers and evaporative crystallizers with forced circulation (FC) and a salt bag for classifying, washing, and cooling the crystallized salt.

- Horizontal, multi-stage crystallizers with air mixing to suspend the salt.

Frequently Asked Questions

What is the main difference between draft tube baffled and forced circulation crystallizers?

Draft tube baffled crystallizers (DTB crystallizers) utilize a mechanical stirrer and clarifying ring for circulation, while forced circulation crystallizers create circulation through pumps, making them suitable for different applications.

How important is the maintenance of crystallizers?

Regular maintenance is crucial to ensure the performance and lifespan of crystallizers, with maintenance-friendly designs chosen from the outset due to many years of experience and close customer interaction.

What impact does temperature have on crystallization?

Temperature is partly the decisive factor that affects solubility and thus supersaturation, which is critical for the initiation of crystallization.

How can crystal size be controlled?

By adjusting operating conditions such as temperature, circulation rate, and degree of supersaturation, the size and quality of the crystals can be precisely controlled.