Crystallization of FeSO₄ 7H₂O

In the production of titanium dioxide using the sulfate process, systems for the removal of iron sulfate, which is a byproduct of this process, are commonly used. Here, iron sulfate usually does not appear as the main component in the solution. This typically contains a high concentration of sulfuric acid (H₂SO₄).

Iron sulfate is most often produced either as iron sulfate monohydrate (FeSO₄ H₂O) or as iron sulfate heptahydrate (FeSO₄ 7H₂O), commonly referred to as Green Vitriol.

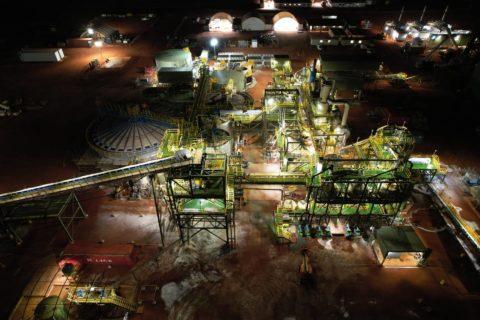

Crystallization Plant for Iron Sulfate Heptahydrate

For the production of FeSO₄ 7H₂O (Green Vitriol), the process of cool crystallization is typically used due to the solubility characteristics. This can be done specifically through:

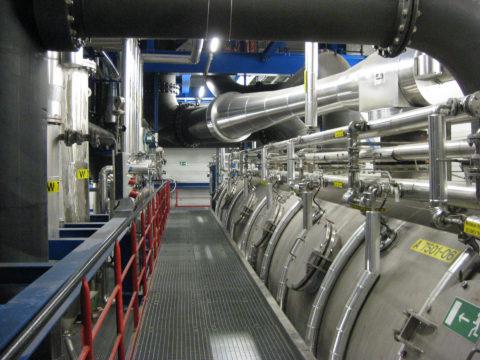

Due to the usual high content of sulfuric acid, the material selection for the equipment is crucial.

This requires considering not only the corrosion effects of the acidic solution but also the abrasive effects of the contained salt. Therefore, steel-rubber lined crystallizers and heat exchangers with carbon tubes have become established in practice.

Due to the relatively moderate boiling point elevation at low temperatures, traditional condensation in mixed condensers or surface condensers with cooling water is preferred, or for achieving lower temperatures of the final solution and thus higher yield of separated FeSO₄ 7H₂O, direct condensation in sulfuric acid is favored.

Crystallization Plant for Iron Sulfate Monohydrate

Besides the production of iron sulfate heptahydrate, it is also possible to crystallize FeSO₄ H₂O.

The corresponding conversion temperature to heptahydrate must be exceeded here. This is strongly dependent on the sulfuric acid content and can range between 10°C and about 60°C.

Typically, at low conversion points, the following are used:

- Vacuum cooling crystallization in several stages

- Surface cooling crystallization in a single stage

At high conversion points, live steam-heated systems are used.

This involves evaporating the solution and concentrating the acid, reducing the solubility of iron sulfate so that depending on the degree of evaporation, residual iron sulfate contents of less than 30 g/l can be achieved.

Higher degrees of evaporation, conversely, cause higher boiling point elevations due to the concentration of sulfuric acid, thereby reducing the possible number of stages of the plants at high concentrations.

In any case, high-quality materials are also required for this type of plant due to the high corrosion potential of the solution, such as steel-rubber lined equipment and heat exchangers with carbon tubes.

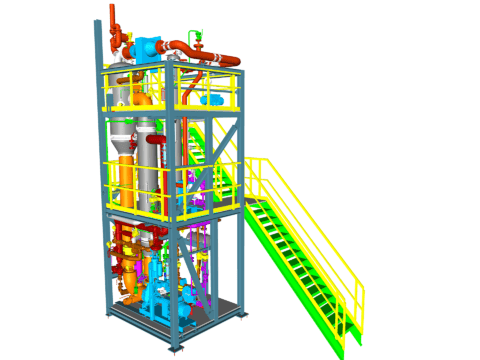

EBNER – your competent partner in plant engineering

With many years of experience in various industrial sectors and with different solutions, EBNER is your contact for the process design, planning, delivery, and erection to optimally execute according to your needs

Frequently Asked Questions

Can other hydrations of iron sulfate be crystallized?

In principle, it is also possible to crystallize:

- Iron sulfate tetrahydrate FeSO₄ 4H₂O

- Anhydrous iron sulfate FeSO₄

To design crystallization plants for FeSO₄ 4H₂O, however, a small temperature range must be maintained, which is why such plants can only have one stage.

To crystallize anhydrous FeSO₄, on the other hand, evaporation must occur at very high temperatures or high sulfuric acid concentrations. This is not common in practice due to the issue of corrosion.

Can FeSO₄ solutions also be operated with plants using thermal vapor recompression or mechanical vapor recompression?

In the evaporation of FeSO₄ solutions and crystallization of FeSO₄ H₂O, this is fundamentally possible.

However, the high boiling point elevation of the solution makes such processes uneconomical.

Other applications