Crystallization of Li₂SO₄ H₂O

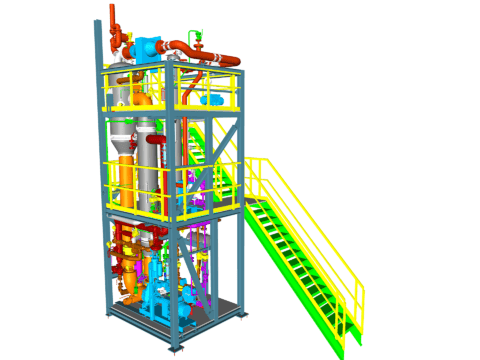

In crystallization plants for lithium sulfate (Li₂SO₄), the mechanical vapor recompression process is primarily utilized.

Owing to the low boiling point elevation of saturated lithium sulfate solutions, one can anticipate low electrical energy consumption per ton of produced lithium sulfate.

Due to the high transition temperature from the monohydrate Li₂SO₄ H₂O to anhydrous Li₂SO₄, typically Li₂SO₄ H₂O is crystallized.

Considering the common binary mixtures of lithium sulfate with sodium sulfate, plants can be designed with two stages. Depending on the application, the conversion of lithium sulfate to lithium carbonate (Li₂CO₃) through the addition of sodium carbonate (Na₂CO₃) can also be accomplished.

Another method for processing lithium sulfate involves adding caustic soda (NaOH), facilitating the crystallization of lithium hydroxide (LiOH) and sodium sulfate (Na₂SO₄).

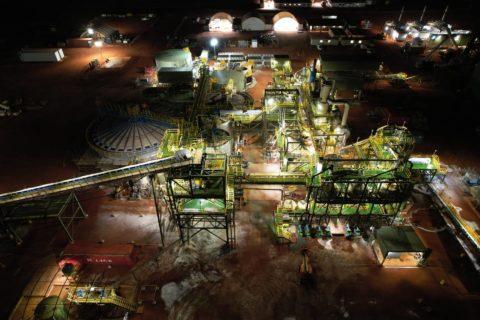

EBNER – your competent partner in plant engineering

Leveraging years of experience across various industrial sectors and with different solutions, EBNER is your go-to partner for executing optimal process design, planning, delivery, and erection tailored to your needs.

Frequently Asked Questions

Can another process be applied for the crystallization of Li₂SO₄ H₂O?

Essentially, any process that surpasses the solubility curve through evaporation from the solution can be employed. These include:

- Evaporation Crystallization for Li₂SO₄ H₂O using mechanical vapor recompression

- Evaporation Crystallization for Li₂SO₄ H₂O using thermal vapor recompression

- Multi-effect Evaporation Crystallization for Li₂SO₄ H₂O in steam-heated plants

What other processing options are available?

In addition to direct crystallization of Li₂SO₄ H₂O, particularly the conversion by adding sodium carbonate to the solution is a common industrial step. This facilitates the crystallization of Li₂CO₃, a key component in battery manufacturing.

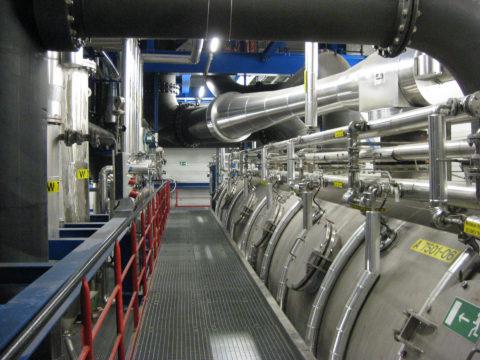

Are there any special requirements for the material selection of the plant?

Due to the high sulfate content and typical absence of chlorides or similar substances in the solution, stainless steels are employed in evaporation plants for Li₂SO₄ H₂O solution and crystallization, which EBNER also standardly uses for other apparatuses.

Other Applications