Crystallization of LiOH H₂O

A significant source of lithium ions for use in battery technologies is the salt lithium hydroxide monohydrate.

This can be obtained either through raw solution or from the silicate spodumene.

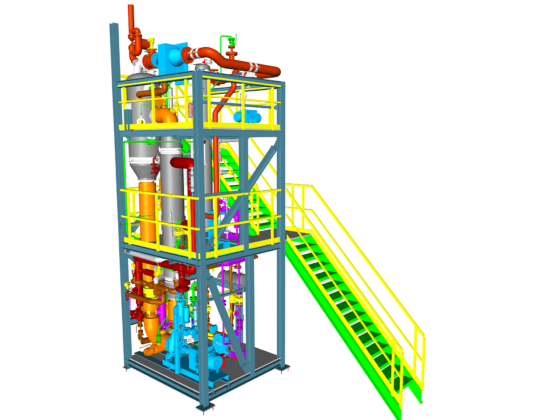

In the production process using spodumene, lithium sulfate solution is first created, which is then converted by reacting with NaOH. The components LiOH and Na₂SO₄ can then be crystallized from their respective solutions using crystallization processes.

Depending on the desired hydration of lithium hydroxide (LiOH or LiOH H₂O), the solution is evaporated at higher or lower temperatures.

A unique aspect of crystallization plants for LiOH is the behavior of LiOH crystals with air. They spontaneously react with the CO₂ present in the air and transform into Li₂CO₃.

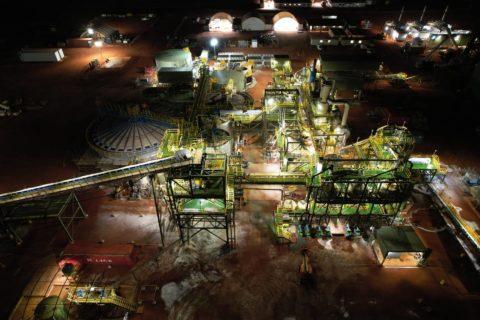

EBNER – your competent partner in plant engineering

With many years of experience in various industrial sectors and with a variety of solutions, EBNER is your contact for optimally executing the process design, planning, delivery, and erection according to your needs.

Frequently Asked Questions

What methods are suitable for the crystallization of LiOH or LiOH H₂O?

Due to the thermodynamic parameters of the solution, various possibilities exist for the crystallization of lithium hydroxide or lithium hydroxide monohydrate:

- Evaporation crystallization plants with fresh steam heating

- Evaporation crystallization plants with mechanical vapor recompression

- Evaporation crystallization plants with thermal vapor recompression

How are different qualities of LiOH H₂O crystals achieved?

Generally, in crystallization plants for lithium hydroxide monohydrate (LiOH H₂O), a first step of crystallization is usually carried out to produce salt of technical purity.

In a second step, the LiOH H₂O crystals are then redissolved and recrystallized to produce a lithium hydroxide salt that meets the purity requirements for battery manufacturing.

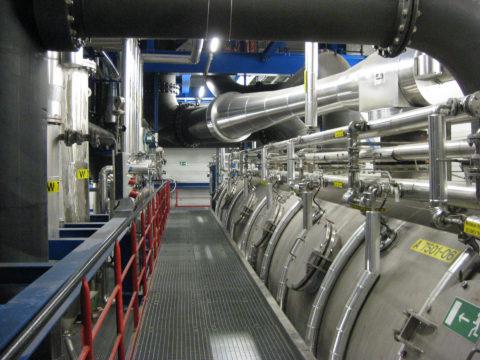

What measures are necessary to prevent the reaction of LiOH crystals with CO₂?

In general, the entire process in and after the crystallization plant for LiOH H₂O must be designed in such a way that no CO₂ comes into contact with the crystals. This can be achieved, for example, by:

- Using CO₂-free water for process purposes

- Overlaying the solution/crystals with nitrogen, for example, during concentration and centrifugation

- Drying the crystals in CO₂-free air

Other applications