Circulation Evaporators

Functioning and Process of Circulation Evaporators

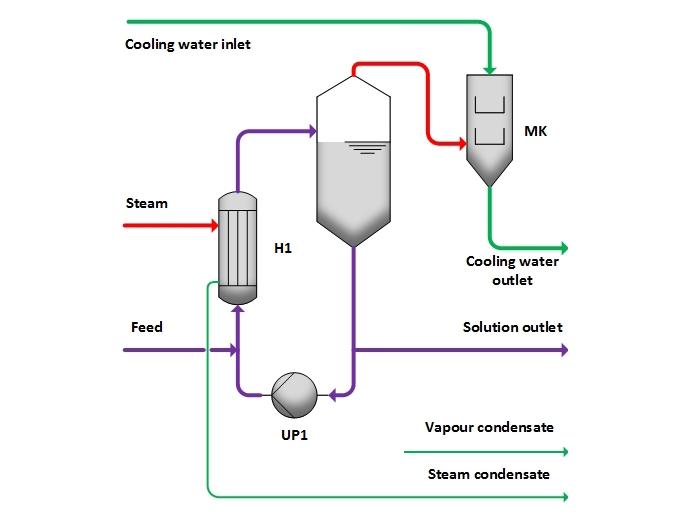

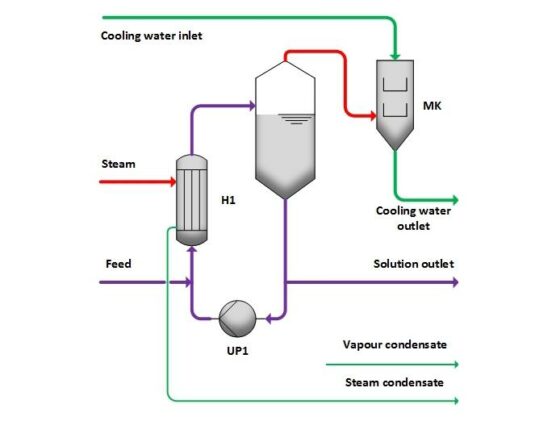

In a circulation evaporator, the solution to be concentrated is continuously circulated through one or more heat exchangers, typically placed outside the evaporator and designed as shell and tube or plate heat exchangers. The circulation can occur through thermosiphon action (natural circulation) or using circulation pumps or air circulation (forced circulation).

The heat exchangers are heated with a hot medium, usually fresh steam.

In EBNER circulation evaporators, the heat exchangers are positioned below the solution level, thereby avoiding premature evaporation of the solution in the heating tubes due to hydrostatic pressure. This minimizes the settling and caking of solution components on the heating surface.

To reduce costs, especially for large evaporation capacities, circulation evaporators are also designed in multiple stages or combined with mechanical or thermal vapor compression.

Circulation Evaporators Principle

Circulation evaporators utilize the continuous circulation of solutions through external heat exchangers to enable efficient evaporation and concentration of solutions, while simultaneously minimizing the risk of deposits and caking.

Advantages

- Minimization of Deposits: Prevents caking by submerging the heating surfaces.

- Flexibility: Adaptation to different evaporation capacities and solutions.

- Energy Efficiency: Possibilities for heat recovery through multi-stage designs.

- Adaptability: Various circulation methods for specific applications.

Variants

- Multi-stage Design: Increased energy efficiency through the use of several evaporation stages.

- Vacuum Circulation Evaporator: Enables evaporation at lower temperatures.

- Forced Circulation Evaporator: Uses a pump for continuous circulation.

- Natural Circulation Evaporator: Utilizes natural convection and density differences caused by temperature differences to allow liquid circulation without pumps, potentially saving energy costs.

- Vapor Compression: Integration of mechanical or thermal vapor compression for energy saving.

- Type of Heat Exchanger: Choice between shell and tube and plate heat exchangers.

- Type of Circulation: Options for natural circulation or forced circulation using a pump or air.

Frequently Asked Questions

How is the formation of deposits in the circulation evaporator minimized?

By placing the heat exchangers below the solution level and using hydrostatic pressure, premature vaporization is avoided.

How does a vacuum circulation evaporator work?

Vacuum circulation evaporators combine the technique of circulation evaporation with the advantages of operating under vacuum. The reduced pressure in the system lowers the boiling point of the solution to be concentrated, allowing evaporation at lower temperatures. This is particularly beneficial for temperature-sensitive substances as it minimizes thermal stress and allows for gentler processing. Additionally, this variant can be more energy-efficient as less thermal energy is needed to reach the boiling point.

How does a forced circulation evaporator work?

The forced circulation evaporator, also known as a Forced Circulation Evaporator, is a special type of circulation evaporator where a pump is used to circulate the fluid through the evaporation system, ensuring a constant flow rate. This technique is particularly used for solutions that tend to crystallize or form scale at slower flow rates or higher temperatures. Forced circulation minimizes the formation of deposits on the heating surfaces as the fluid is constantly in motion, reducing the opportunity to settle or deposit on surfaces. This allows for more efficient evaporation and reduces the likelihood of operational interruptions due to cleaning or maintenance.

How does a natural circulation evaporator work?

A natural circulation evaporator uses natural convection to circulate liquids without the use of a pump. The liquid is heated, forms vapor bubbles, and these rise due to their lower density. This rise causes a circulation of the liquid, with the hot liquid rising and the cooler liquid sinking, creating a continuous cycle and evaporation process. This principle enables efficient evaporation and concentration of solutions without mechanical pumps.

What are the advantages of the multi-stage design of circulation evaporators?

Multi-stage circulation evaporators provide improved energy efficiency by utilizing the exhaust steam in the subsequent evaporation stage.

Can the circulation evaporator be adapted to different solutions?

Yes, by choosing the type of circulation and heat exchanger, the circulation evaporator can be optimized for specific solutions and requirements.

How does vapor compression contribute to energy efficiency?

By recirculating and utilizing the energy of the vapor in the evaporation process, energy can be saved, thereby increasing efficiency.

Is the circulation evaporator suitable for high-viscosity solutions?

The design and circulation methods of the circulation evaporator can be adapted for handling various solution properties, including high viscosities.

Other Processes