Vacuum Salt (NaCl) from Brine

EBNER was awarded the contract for the planning and delivery of a plant for the production of high-purity table salt (NaCl) from brine using an evaporation crystallization plant based on the principle of mechanical vapor recompression by a table salt producer in Russia before the year 2020.

- Region: Russia

- Type of Plant/ Process: Evaporation Crystallization Plant with Mechanical Vapor Compression

- Services: Engineering, Manufacturing, Erection Supervision, Commissioning Supervision

Innovative Salt Production: From Cavern Leaching to Packaging

Initially, the brine is extracted by leaching from a cavern and pre-cleaned in a brine purification stage. The evaporation plant operates with mechanical vapor recompression using fans, meaning electrical energy is used for evaporation instead of steam energy.

A so-called salt bag is attached to the crystallizer, through which the produced NaCl salt is cleaned and cooled. The crystal size of the sodium chloride can also be adjusted using such a device.

The produced NaCl salt is separated and fed into the drying, packaging, and storage system.

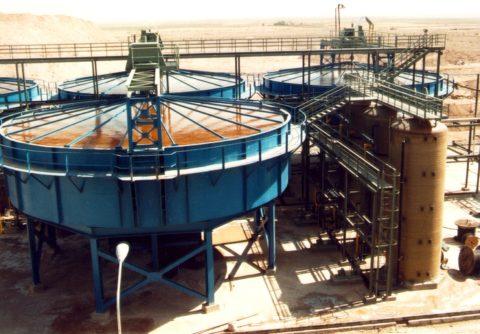

In the course of this project, EBNER was able to demonstrate its competence for challenging on-site assemblies once again. The crystallizer with a diameter of over 5.4 m was prefabricated in pieces in the in-house halls and assembled on-site at the customer’s premises. A major challenge was the high-quality material and the associated complex welding work, including post-treatment under adverse conditions.

EBNER was awarded this contract primarily for two reasons:

Firstly, the customer had bad experiences with a previously built plant by a competitor of EBNER. Secondly, the customer was aware of a plant already built for a client in Austria and was convinced of the overall competence during the inspection of this plant and discussions with EBNER.

Technical Data of the Plant:

- Feed rate of solution: 88 m³/h

- Main components of the solution: NaCl, Na₂SO₄

- Water evaporation: 68 t/h

- Product: NaCl

- Production volume: 21 t/h

Scope of Supply

EBNER’s scope of supply with company personnel included, among others:

- Basic and detail engineering incl. design of main components

- Manufacturing of main components

- Erection supervision of the entire plant incl. steel construction

- Performing welding works with company’s own personnel using equipment and pipelines provided by the customer

- Commissioning supervision of the entire plant

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References