Mechanical Vapor Recompression

Functioning and Process of Mechanical Vapor Recompression

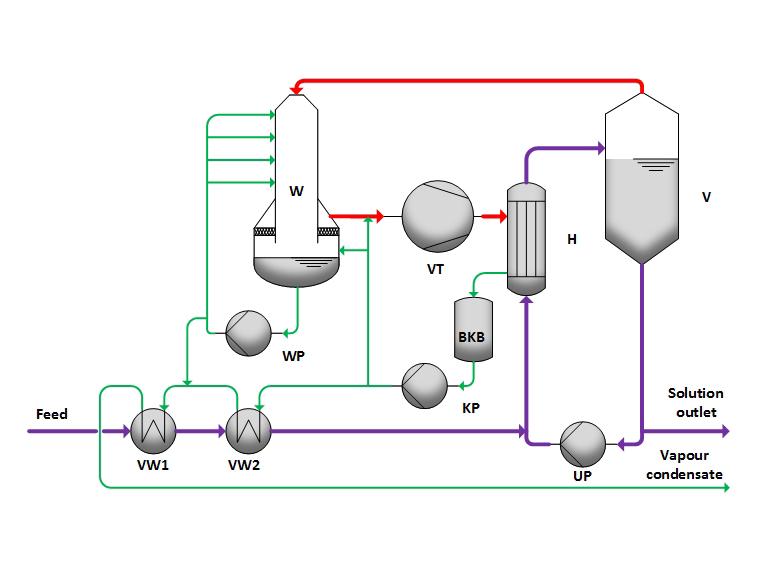

The solution is first preheated in preheaters VW1, VW2 with condensate and then enters the evaporator circuit. Here, it mixes with the circulating solution and is heated in the heating body H. In the evaporator V, the solvent, typically water, evaporates, cooling the solution to the boiling temperature. The resulting vapor steam is washed and saturated with condensate in the vapor scrubber W and compressed to a higher pressure and temperature level by the mechanical compressor VT, also known as a mechanical vapor compressor.

This process of mechanical vapor recompression allows for the steam to be used as a heating medium for the warming of the circulated solution. With continuous concentration and exceeding the saturation line, crystals form, creating a suspension. This can be separated in the centrifuge Z into moist crystals and solution. The solution is returned to the plant by the recirculation units RB and RP, while the salt is dried in the dryer T.

Mechanical Vapor Recompression Principle

Mechanical vapor recompression allows for the vapor steam, which is generated by the evaporation of the solution, to be compressed to a higher pressure and temperature level using electrical energy. This enables the vapor steam to be used as an efficient heating medium for the warming of the circulated solution.

Advantages of the Process

- Low energy costs, as only a fraction of the evaporation energy needs to be provided in the form of electrical energy.

- Typically, only electrical energy is needed as an energy source.

- Typically, no steam is needed in normal operation, only for startup.

- No cooling water needed for vapor condensation.

- Suitable for various applications.

- Retrofitting in existing plants is possible.

Types of the Plant

- With multiple fans or with a turbo compressor.

- Different preheating concepts.

- With or without vapor scrubber.

- With or without salt separation.

Frequently Asked Questions

What is the main advantage of mechanical vapor recompression?

The main advantage lies in the low energy costs, as only a fraction of the evaporation energy is required in the form of electrical energy.

Is mechanical vapor recompression suitable for all industries?

Yes, it is versatile and can contribute to energy saving and process optimization in various industries.

Can mechanical vapor recompression be retrofitted in existing plants?

Yes, retrofitting in existing plants is generally possible and can contribute to process optimization.

How does mechanical vapor recompression differ from thermal vapor recompression?

The main difference between mechanical and thermal vapor recompression lies in the way the vapor steam is compressed. In mechanical vapor recompression, the steam is compressed to a higher pressure level using mechanical compressors, such as fans or turbo compressors. This method is particularly energy-efficient, as it mainly relies on electrical energy.

Thermal vapor recompression, on the other hand, uses steam jet devices and motive steam to compress the vapor steam to a higher pressure and temperature level, allowing it to be used as a heating medium.

Other Processes