Thermal Vapor Recompression

Functioning and Process of Thermal Vapor Recompression

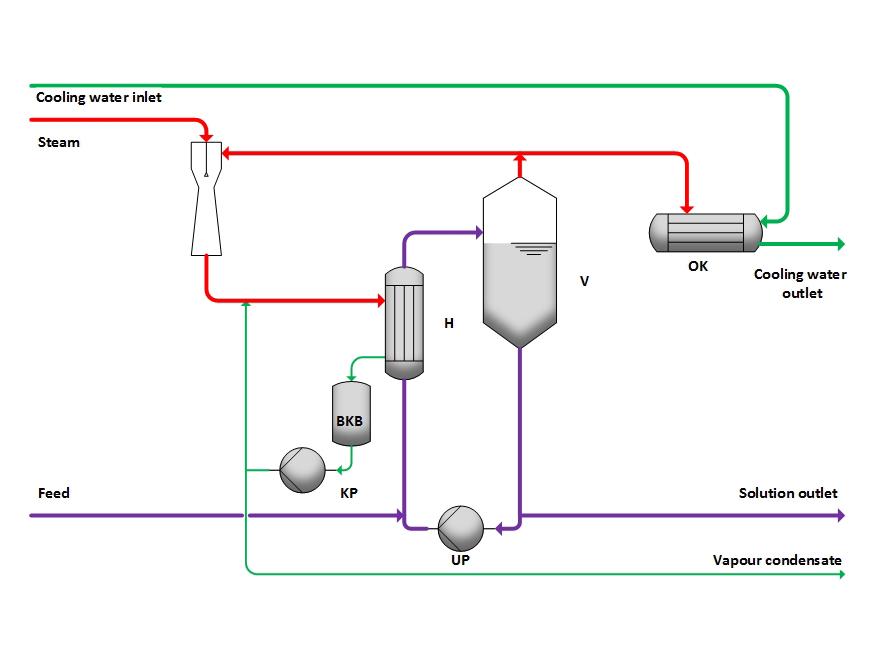

The solution is first preheated with condensate and then enters the evaporator circuit. There, it mixes with the circulating solution and is heated in the heating body H. In the evaporator V, the solvent, usually water, evaporates, cooling the solution to the boiling temperature. The resulting vapor steam is compressed to a higher pressure and temperature level using steam in the steam jet apparatus, allowing it to be used as a heating medium for warming the circulated solution. This process is also known as thermal vapor recompression. Excess vapor steam is condensed. If necessary, by further evaporation, the solution can be concentrated to the extent that crystals are formed. These can then be separated from the solution and dried, if desired.

Thermal Vapor Recompression Principle

Thermal vapor recompression is a process where a part of the vapor steam is compressed to a higher pressure and temperature level using a steam jet apparatus. This allows the vapor steam to be used as an efficient heating medium, which can save energy and optimize processes.

Advantages

- Only a part of the evaporation energy needs to be provided in the form of fresh steam.

- Low investment costs.

- Retrofitting in existing plants is possible.

- Suitable for various applications.

Variations

- Number of stages: Increasing the number of stages to reduce the consumption of fresh steam.

- Salt separation: Optional separation of salt from the solution.

- Preheating concepts: Different concepts for preheating the solution.

Frequently Asked Questions

What does thermal vapor recompression achieve?

It enables the compression of vapor steam to a higher pressure and temperature level, allowing it to be used as a heating medium.

Why is vapor condensation necessary?

Vapor condensation is necessary to condense excess vapor steam.

Can thermal vapor recompression be retrofitted in existing plants?

Yes, thermal vapor recompression can often be retrofitted in existing plants to optimize processes and save energy.

Other Processes