High-Value Potassium Sulfate (SOP) from Wastewater

EBNER was awarded a contract by a saltworks in Austria for the planning, delivery, and erection of a plant mainly for the production of high-purity potassium sulfate (SOP) from so-called mother liquor through a combined and patented circuit of cooling and evaporation crystallization.

- Region: Austria

- Type of Plant: Complete Process for the Production of Potassium Sulfate (SOP)

- Services: Engineering, Manufacturing, Erection, Commissioning Supervision

Revolutionary Technology: Potassium Sulfate from Saline Wastewater

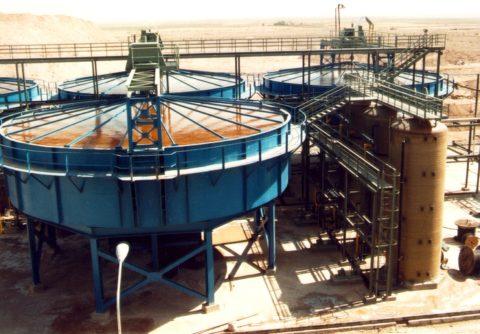

The saltworks processes raw brine into marketable food-grade or road salt through various process steps. Impurities in the raw brine, such as potassium or bromide, cannot be completely removed in the pre-purification processes. Sulfate ions are only partially precipitated according to their solubility. Therefore, these substances must be removed (purged) from the system in a soluble form during the evaporation and crystallization process. This sludged mother liquor was previously discharged into the environment by the customer. Through the plant designed by EBNER in cooperation with a partner, it became possible to produce not only table salt but also the marketable product potassium sulfate from this mother liquor.

Process Steps

The following process steps, among others, are applied:

- Neutralization for pH adjustment

- Evaporation crystallization and sodium chloride production

- Cooling crystallization and glaserite production

- Conversion of sodium sulfate and potassium chloride to potassium sulfate

- Drying and storage of potassium sulfate

The customer is now able to achieve high profit margins with the former waste product that polluted the environment. Due to the customer’s great satisfaction, EBNER later received a follow-up order for a plant for the production of table salt.

Technical Data of the Plant

- Feed rate of solution: 88 m³/h

- Main ingredients of the solution: Na₂SO₄, NaCl, KCl

- Water evaporation: 36 t/h

- Production volume of NaCl: 8.9 t/h

- Production volume of K₂SO₄: 2.5 t/h

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References