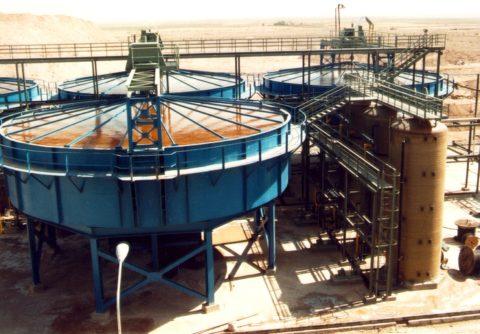

Manufacturing, Delivery, and Erection of Agitated Vessels

EBNER received an order from a renowned German manufacturer of technical construction materials from bitumen for the supply of a total of 7 agitator tanks for a new roofing membrane factory in Austria.

- Region: Austria

- Type of Plant: Agitated Vessel

- Services: Planning, Manufacturing, Erection, Commissioning

Agitators and Agitator Tanks: Complete solutions from EBNER for the mixing unit

The agitators were all equipped with corresponding drive units and delivered in different sizes (12 m³, 15 m³, and 20 m³ volume) as well as with various agitating elements for a wide range of stirring tasks.

All agitators are made of C-steel and have a half-pipe coil on the bottom and jacket side of the tanks for heating the bitumen and the in-mixed fillers using thermal oil.

Customized Agitator Tanks from EBNER

However, the scope of supply included not only the agitators. EBNER also created the entire plant layout in 3D at the customer’s request, for the planning of all relevant subsections, including those of the customer, such as screw conveyors and sifters. The customer also commissioned EBNER to supply the steel construction (incl. stairs, grating, and railings), tank insulation, as well as the delivery of a control cabinet with measuring and control technology for controlling the sub-plant and integration into the customer’s control of the entire plant. In addition, EBNER also took over the complete mechanical and electrical on-site erection including commissioning and handover to the long-standing customer.

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References