Crystallization from Process Liquors

EBNER was awarded the contract for the planning and supply of two evaporation crystallization plants for process liquors from a renowned, globally operating potash and salt producer based in Germany.

- Region: Germany

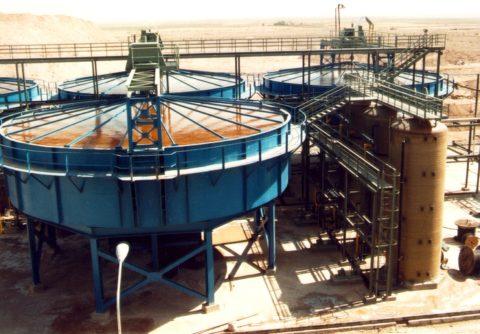

- Plant Type: Multi-effect Evaporation Crystallization Plants

- Services: Engineering, Manufacturing, Erection, Commissioning

Process Optimization through Salt Crystallization: Four-effect and Two-effect Plants in Operation

The process liquors are heated in a four-effect and a two-effect plant with fresh steam to the boiling point, evaporating water in the process. This exceeds the solubility of some salts in the liquor, causing salt to crystallize. The plants operate on the counter-current principle, meaning the feed liquor is introduced to the coldest stage and then sequentially directed to the hottest stage. The suspension in the hottest stage then exits the plant or is pumped out and taken over by the customer.

The challenge of the plants lay in selecting suitable materials and coatings resistant to aggressive media. For the main components, steel-rubber was used, and high-grade titanium and aluminum bronze were processed.

EBNER was awarded this contract mainly because the customer had been working with EBNER for several decades and always responded quickly and competently to customer requirements in plant and apparatus design and construction and services for ongoing work. EBNER met these expectations, leading to another important large project contract from the customer.

Technical Data of the Plant

Four-Effect Evaporation Crystallization Plant:

- Feed rate of solution: 135 m³/h

- Main components of the solution: MgCl₂, NaCl, KCl, MgSO₄

- Water evaporation: 47 t/h

- Product: KCl, NaCl, Kainite

- Production volume: 23 t/h

Two-Effect Evaporation Crystallization Plant:

- Feed rate of solution: 80 m³/h

- Main components of the solution: MgCl₂, NaCl, KCl, MgSO₄

- Water evaporation: 30 t/h

- Product: Langbeinite

- Production volume: 4.3 t/h

Scope of Supply

EBNER’s scope of supply with company personnel included, among others:

- Basic and detailed engineering incl. design of main components

- Manufacturing of main components

- Erection of the entire plant

- Commissioning of the entire plant

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References