Evaporation Plant for Radioactively Contaminated Wastewater

EBNER was awarded the contract for the planning, delivery, and erection of a plant for the evaporation of radioactively contaminated wastewater for the dismantling of a nuclear power plant in Germany.

- Region: Germany

- Type of Plant: Single-Effect Evaporation

- Services: Engineering, Manufacturing, Erection, Commissioning Supervision

Safe Decontamination: Evaporation Plants Clean and Reduce Radioactive Wastewater

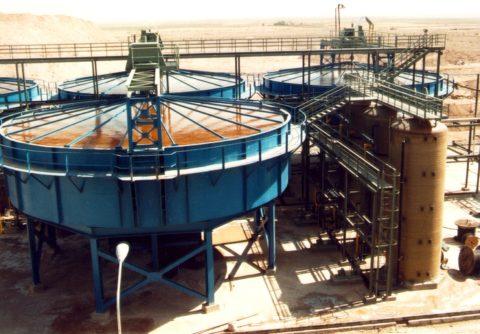

During the dismantling of a nuclear power plant, the radioactively contaminated equipment is crushed and then decontaminated. This is usually done by thoroughly washing these equipment. This process generates radioactively contaminated wastewater, which is processed in an evaporation plant.

The objective of the evaporation plant is to purify the wastewater to such an extent that reuse of the distillates or discharge into the effluent is possible in compliance with regulations. The wastewater volume is minimized, leading to a significant reduction in landfill costs. The wastewaters are stored in raw water tanks and evaporated in the evaporation plant after pretreatment. In this process, the salts and solids in the wastewater are concentrated by removing water.

From Concentrate to Reuse: Process of Processing Radioactive Residues

The concentrate is pumped from the evaporator to a concentrate container and then transferred to the drying plant for further treatment. After drying, the residue is stored in interim and final disposal sites. The resulting vapor is passed through a droplet separator and further purified in a column because a high decontamination factor (1:1,000,000) must be maintained in the vapor or distillate. The vapor is then condensed using cooling water in a surface condenser. The distillate is directed to the distillate tank and, after analysis and approval, reused as rinse water or discharged.

EBNER was awarded this contract primarily due to the continuous quality assurance throughout the project and the high manufacturing quality of the components.

Technical Data of the Plant

- Wastewater feed rate: 3 m³/h

- Water evaporation including rinse water for washing the vapor: 4 t/h

Scope of Supply

EBNER’s scope of supply with company personnel included, among others:

- Basic and detail engineering incl. design of main components

- Manufacturing of main components

- Commissioning supervision of the entire plant with reference-solution

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References