Falling Film Evaporators

Falling Film Evaporators Functioning and Process

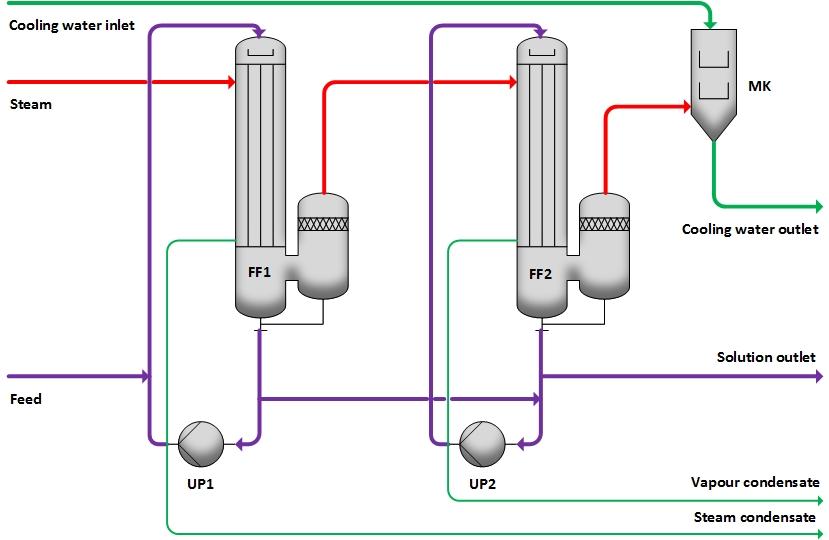

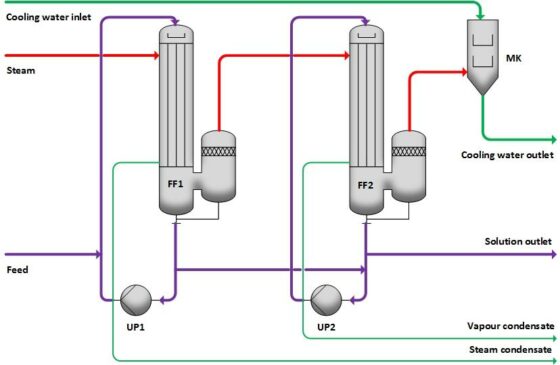

In the example shown, the solution is fed into the circulation line of the first stage, mixing with the circulating solution. In the evaporator tubes, it is partially evaporated by fresh steam. In the lower area of the evaporator FF1 and in the subsequent separator, the liquid is separated from the vapor. The vapor flows to the second stage, which operates under reduced pressure and serves as a heating medium. The vapor generated in the second stage is finally condensed with cooling water in the mixing condenser MK.

Falling Film Evaporators Principle

In falling film evaporators, the solution is evenly distributed over the tubes from the top tube sheet, flowing down as a thin liquid film. Heat application leads to evaporation. Both the vapor (vapour) and the solution flow downwards.

Advantages of Falling Film Evaporators

- Gentle Evaporation: Ideal for heat-sensitive solutions due to the continuous renewal of the liquid film.

- Cost Efficiency: Lower investment costs compared to circulation evaporators.

Variants

- Number of Stages: Increasing the number of stages can reduce steam consumption.

- Compressors: The use of mechanical or thermal compressors can further minimize fresh steam consumption.

- Preheating Concepts: Different preheating concepts can be integrated to adapt the process to specific conditions.

- Condensation: The vapor of the last stage can be condensed using mixing condensers or surface condensers.

- Solution Entry Point: The solution can be introduced into either the first stage (co-current) or the last stage (counter-current), resulting in either cold or hot discharge of the concentrate from the system.

Frequently Asked Questions

Why are falling film evaporators suitable for heat-sensitive solutions?

The continuous renewal of the liquid film and gentle evaporation minimize the thermal stress on the solution, which is particularly advantageous for heat-sensitive substances.

How is the solution distributed in a falling film evaporator?

A special device at the top tube sheet evenly distributes the solution onto the tubes, where it flows down as a thin film along the tubes.

Can falling film evaporators operate in multiple stages?

Yes, falling film evaporators can operate in single or multiple-stage configurations, with the vapor from the previous stage serving as a heating medium for the next.

How are vapor and concentrated solution separated in a falling film evaporator?

In the lower area of the evaporator and in subsequent separators, vapor and concentrated solution are separated to obtain a pure vapor phase and a concentrated liquid phase.

Other Processes