Flash Evaporators

Operation and Procedure of Flash Evaporators

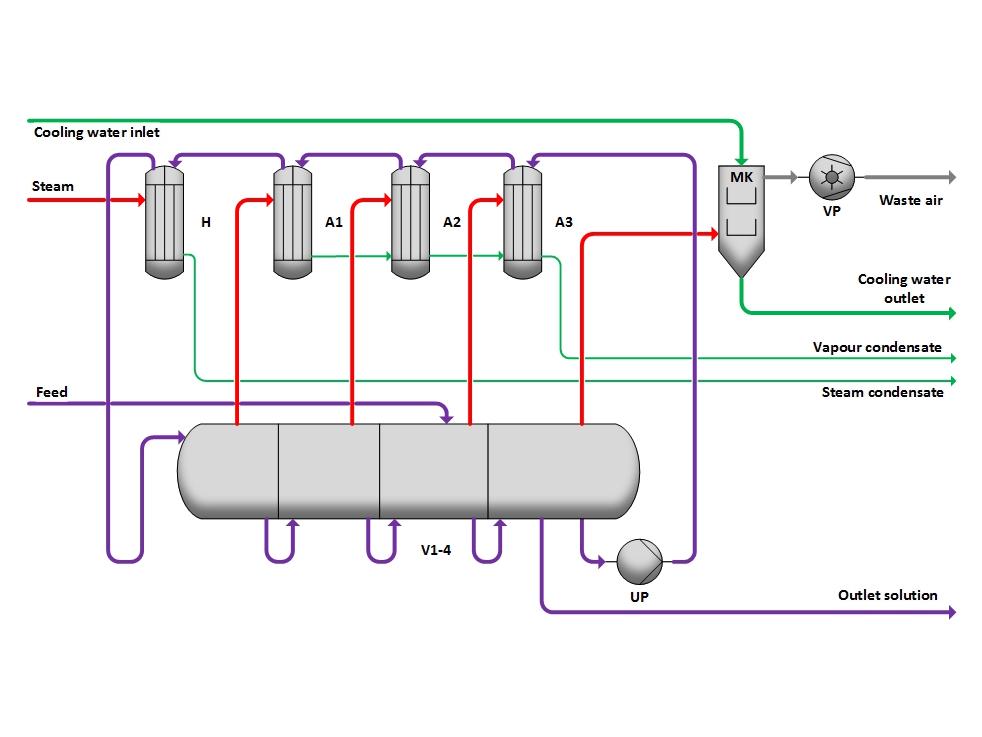

The solution is initially fed into a specific stage of the evaporator (V1-4) and mixes with the circulating solution. From the last stage of the evaporator, the solution is moved by the circulation pump UP through the heaters (A3, A2, A1) and heated with the vapors from the evaporator V1-4. At the end of the heat recovery, energy in the form of exhaust steam and/or fresh steam is supplied to the heater H.

Then, the solution passes through the evaporator stages, where the solvent (water) progressively evaporates under decreasing pressure as the solution cools to the boiling point. The resulting vapor is used in the heaters to warm the circulating solution. The vapor from the last stage is condensed with cooling water in the mixing condenser MK. The inert gases are extracted with a vacuum pump VP.

The concentrated solution exits the plant from a specific stage of the evaporator, depending on the desired temperature.

Flash Evaporators Principle

Flash evaporators employ the principles of pressure reduction and adiabatic evaporation of the solvent to crystallize salt from a solution. This process lowers the solubility of salt by reducing the temperature, leading to crystallization.

Advantages

- Low fresh steam consumption: Depends on the number of stages and temperature gradient.

- Maximum operating times: Prevents scaling on heating surfaces.

- Flexibility and versatility: Allows for partial load operation and diverse applicability.

Variants

- Increasing the number of stages: Reduces fresh steam consumption.

- Different preheating concepts: Adaptation to specific process requirements.

- Vapor condensation: Utilization of mixing condensers or surface condensers.

- Multi-stage flash evaporators: Enhances efficiency by using multiple evaporation stages.

Frequently Asked Questions

How are flash evaporators energetically optimized?

By multi-stage preheating and using the vapor to warm the circulating solution, energetic optimization is achieved.

What role does the mixing condenser play in the process?

The mixing condenser condenses the vapor from the last stage(s) with cooling water to cool the solution to the desired temperature.

Why is a vacuum pump used in flash evaporators?

The vacuum pump extracts inert gases and enables effective pressure control in different stages of the evaporator.

How is the concentrated solution discharged from the flash evaporator?

The concentrated solution exits the plant from a specific stage of the evaporator, selected based on the desired temperature.

Other Processes