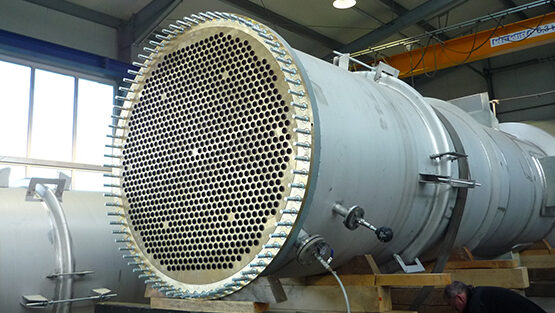

Shell and Tube Heat Exchangers

Shell and tube heat exchangers ensure efficient heat transfer in various industrial applications. These devices use metallic tubes in welded or rolled designs or carbon tubes to transfer heat.

Advantages of Shell and Tube Heat Exchangers

- Universal application areas: The design allows for use with a wide variety of media. Especially for media containing solids, shell and tube heat exchangers are the first choice.

- Maintenance-friendly: Typically, individual tubes can be replaced instead of entire components.

- Custom manufacturing: Tailor-made to meet specific customer requirements and operational conditions.

Types of Shell and Tube Heat Exchangers

EBNER manufactures shell and tube heat exchangers with metallic tubes in welded and rolled designs, including materials such as:

- Carbon steel: Known for its robustness and cost-effectiveness, carbon steel is a classic choice for a variety of heat transfer applications.

- Titanium and titanium-clad: This material is valued for its exceptional corrosion resistance and strength at a low weight, ideal for aggressive environments and chloride stress.

- Aluminum-bronze: Excellent corrosion resistance, especially against seawater or in the potash industry.

- Various stainless steels: Stainless steels offer an excellent ratio of price to corrosion resistance and are suitable for high and low temperatures.

- Nickel-based materials: Optimal for extremely high temperatures and corrosive media, these materials ensure both thermal and mechanical stability.

- Carbon: With high heat transfer coefficients and corrosion resistance against strong acids, it is the choice for the spinning bath industry.

In addition to heat exchangers with metallic tubes, heat exchangers with carbon tubes (graphite) are also manufactured.

At EBNER, these are individually inserted with sealing rings into rubber-lined tube sheets, allowing each tube to expand freely. This eliminates the need for sealing a tube plate with a stuffing box, which would otherwise have to accommodate the expansion of the entire tube bundle and could cause tube breaks during temperature fluctuations. It also allows for the replacement of individual tubes, as opposed to standard construction where the entire graphite component must be replaced if individual tubes fail.

Frequently Asked Questions

What distinguishes EBNER shell and tube heat exchangers from standard models?

EBNER’s heat exchangers are distinguished by their tailor-made construction and a variety of materials.

What materials are used to manufacture shell and tube heat exchangers at EBNER?

The heat exchangers are made from various materials such as carbon steel, titanium, aluminum-bronze, various stainless steels, nickel-based materials, and carbon.

How is the longevity of the devices ensured?

The use of high-quality materials and a design that minimizes thermal stresses ensures a longer lifespan of the devices.