Regeneration of Spinning Bath and Production of Sodium Sulfate in the Viscose Fiber Industry

EBNER is specialized in the design and construction of complete spinning bath treatment plants and has built numerous plants worldwide since its founding. Numerous patents have made EBNER the world market leader for such plants by the end of the 20th century.

- Region: Germany

- Anlagentyp: Complete Process for Spinning Bath Production

- Leistungen: Engineering, Manufacturing, Erection, Commissioning

Sustainable Spinning Bath Treatment: EBNER’s Innovative Solutions for Viscose Fiber Producers

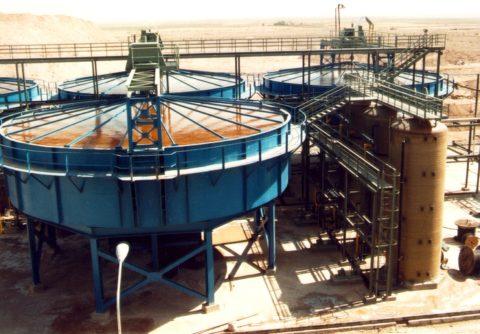

EBNER plants for spinning bath treatment have been operating for several decades at a viscose fiber producer’s factory in Germany. Due to this history and the customer’s satisfaction with the existing plants, EBNER was awarded the contract for the planning, delivery, and erection of a plant for the regeneration of spinning bath and production of sodium sulfate from spinning bath contaminated by the fiber production process.

During the spinning process in viscose fiber factories, a chemical reaction occurs where sodium sulfate and water are formed from sodium hydroxide and sulfuric acid, thereby consuming and diluting the so-called spinning bath. Previously, this spinning bath was used only once and then discharged as wastewater, leading to significant environmental pollution and high operating costs. This necessitated the need to regenerate the spinning bath and reintroduce it into the process, or additionally produce a marketable product from the contained sodium sulfate.

Process Steps

The following process steps are required:

- If necessary, degassing of the spinning bath

- Evaporation of the spinning bath

- Crystallization of Glauber’s salt (Na₂SO₄ 10H₂O) from the spinning bath

- Processing of Glauber’s salt into anhydrous sodium sulfate by melt crystallization (calcination)

EBNER was awarded this contract mainly due to the good experience with EBNER based on a previously completed project to full satisfaction and the outstanding quality of the existing plant. Another reason was the low primary energy consumption in the form of fresh steam.

Technical Data of the Complete Plant

- Spinning bath feed rate: 195 m³/h

- Main components of the solution: Na₂SO₄, H₂SO₄, ZnSO₄

- Water evaporation: 38 t/h

- Product: Na₂SO₄

- Production volume: 7.2 t/h

Scope of Supply

EBNER’s scope of supply with company personnel included, among others:

- Basic and detailed engineering incl. design of main components

- Manufacturing of main components

- Erection of the entire plant

- Commissioning of the entire plant

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References