Large-Scale Plant for the Crystallization of Potassium Chloride (MOP) and Sodium Chloride from Brine

EBNER was awarded the contract for the planning and delivery of several plants for evaporation crystallization and vacuum cooling crystallization from brine for the site in Laos by an EPC on behalf of a state-owned corporation.

The plant designed by EBNER is part of a Green-Field project for the production of various salts, which after several intermediate steps and transformations are used as fertilizer potassium chloride (KCl) and table salt (NaCl).

- Region: Laos

- Type of Plant/Process: Multi-Effect Evaporation Crystallization Plants and Vacuum Cooling Crystallization

- Services: Engineering, Manufacturing, Erection Supervision

Efficient Crystallization: The Transformation of Mixed Salt into High-Purity Table Salt

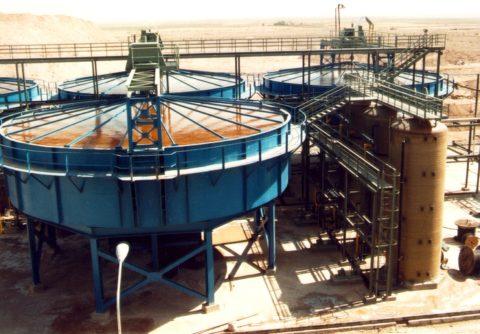

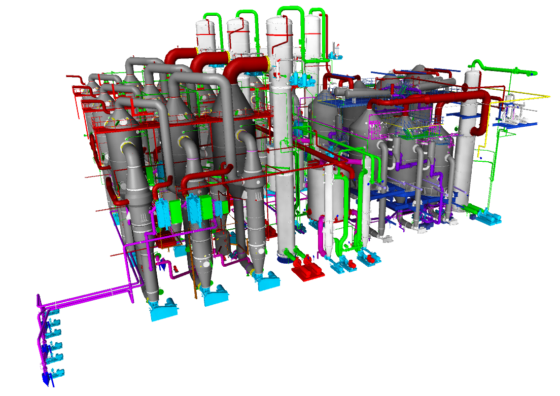

In the first step, brine is extracted through cavern mining and mixed salt is produced in three parallel three-effect evaporation crystallization plants by evaporating water and exceeding the solubility of some of the salts. Subsequently, the salts, mainly NaCl and KCl, are separated and partially re-dissolved by creating a hot solution, resulting in high-purity table salt.

The solution produced in the described plants is then concentrated in another two-effect evaporation crystallization plant, where another mixed salt, mainly carnallite and NaCl, is produced. This is then returned to the three-effect plants for transformation.

The hot solution is then cooled in a seven-effect vacuum cooling crystallization process. This works according to the typical principle of KCl production. As the solubility of KCl decreases with falling temperature, progressive crystallization of salt occurs with progressive temperature reduction. This salt is then sent to the final stage for salt separation and drying.

The plant parts designed by EBNER are the core of the entire facility. EBNER was awarded this contract mainly due to the low energy consumption within the framework of highly efficient heat recovery and the customer’s confidence in the quality of EBNER.

Technical Data of the Plant

Three plants, each as Three-Effect Evaporation Crystallization Plant

- Feed rate of solution: 435 m³/h

- Main components of the solution: KCl, NaCl, MgCl₂

- Water evaporation: 220 t/h

- Product: NaCl, KCl

- Production volume: 84 t/h

Two-Effect Evaporation Crystallization Plant:

- Feed rate of solution: 200 m³/h

- Main components of the solution: KCl, NaCl, MgCl₂

- Water evaporation: 69 t/h

- Product: NaCl, Carnallite

- Production volume: 47 t/h

Vacuum Cooling Crystallization Plant:

- Feed rate of solution: 550 m³/h

- Main components of the solution: KCl, NaCl, MgCl₂

- Water evaporation: 22 t/h

- Product: KCl

- Production volume: 50 t/h

Scope of Supply

EBNER’s scope of supply included, among others:

- Basic and detailed engineering incl. design of main components

- Manufacturing of main components

- Erection supervision for main components of the entire plant

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References