Large-Scale Plant for Wastewater Treatment and Production of Marketable Salt

EBNER was awarded the contract for the planning, delivery, and erection of a plant for the treatment of wastewater and production of marketable salt through an evaporation crystallization plant followed by cooling crystallization by a renowned, globally operating potash and salt producer headquartered in Germany.

- Region: Germany

- Type of Plant/ Process: Multi-Effect Evaporation Crystallization Plant and Cooling Crystallization

- Services: Engineering, Manufacturing, Erection, Commissioning

Benchmark-Setting Plants: EBNER’s Contribution to Comprehensive Environmental Protection Measures

The plant designed by EBNER is part of a package of measures by the customer for wastewater reduction at several plants. These measures represent the largest single investment in the customer’s history across Europe and are of utmost importance due to high media and politics interest. Having worked with EBNER for several decades, the customer trusted EBNER’s expertise for this plant as well. This allowed EBNER to undertake its first project in large-scale plant construction.

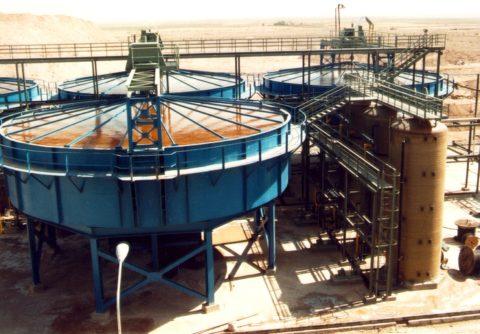

The resulting wastewater is first evaporated in a three-effect evaporation crystallization plant, crystallizing salt. A multi-effect preheating was implemented to ensure minimal primary energy consumption in the form of steam.

The third stage of the plant is so large (evaporator diameter 6.8m) that it was duplicated. The other components of the plant also posed a special challenge. For example, the heater of the second stage, weighing about 120 tons, was the heaviest apparatus ever manufactured by EBNER in one piece.

Complex Salt Processing

After the evaporation crystallization plant, the resulting suspension is fed into four sequential agitator vessels, each with a volume of 250m3, where further salt crystals are precipitated and existing ones grow.

The largest part of the suspension is then sent to a single-effect flash evaporation, where vacuum is applied to evaporate water, lowering the temperature of the suspension.

This is followed by the final step in the EBNER-supplied plant. Here, in a two-effect cooling crystallization, the suspension is further cooled. The cooling media are both cooling water and refrigeration brine from a refrigeration machine.

Strategic Partnership: EBNER Impresses with One of the Customer’s Most Important Investments

As mentioned, this project is of the highest priority for the customer. EBNER was awarded this contract primarily due to the projects already completed for the customer in plant construction, apparatus construction, and service.

This overall competence and the known flexibility and responsiveness of EBNER convinced the customer to make probably the most important investment in the group’s history in Europe with EBNER.

Technical Data of the Plant

- Solution feed rate: 405 m³/h

- Main components of the solution: MgCl₂, NaCl, KCl, MgSO₄

- Water evaporation: 185 t/h

- Product: Kainite, NaCl, KCl

- Production volume: 95 t/h

Scope of Supply

EBNER’s scope of supply included, among others:

- Basic and detailed engineering incl. design of main components

- Manufacturing of main components

- Erection of the entire plant

- Commissioning of the entire plant

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References