Salt Extraction from Desert Sand

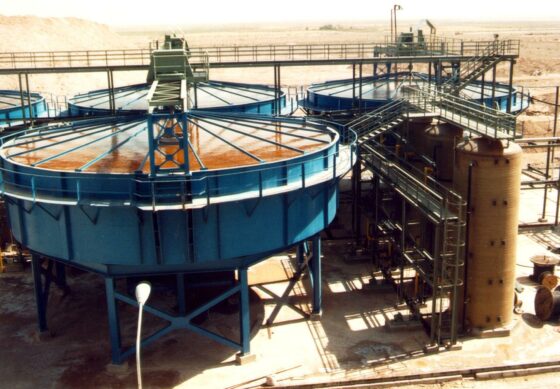

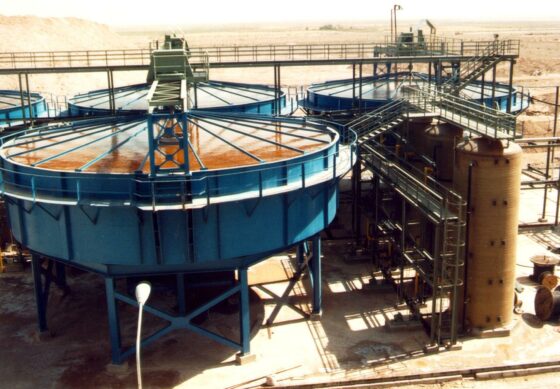

EBNER was awarded the contract for the planning and supply of a plant for the extraction of high-purity sodium sulfate (Na₂SO₄) from “desert sand” in the Middle East. This sand is in the form of a salt layer about 100mm thick on the earth’s crust. This salt layer mainly consists of inorganic salts such as sodium sulfate, sodium chloride, magnesium sulfate, and calcium sulfate.

- Region: Middle East

- Type of Plant: Pretreatment and Vacuum Cool Crystallization with Calcination

- Services: Engineering, Manufacturing, Erection Supervision, Commissioning Supervision

Process Steps

The following process steps, among others, are applied:

- Mining and transportation of the raw salt to the plant

- Dissolving the raw salt, removing unwanted, insoluble components and creating an aqueous solution

- Crystallizing the salts in the aqueous solution through cooling crystallization, removing soluble components and producing Glauber’s salt (sodium sulfate with adherent water)

- Melting Glauber’s salt and producing sodium sulfate (calcination)

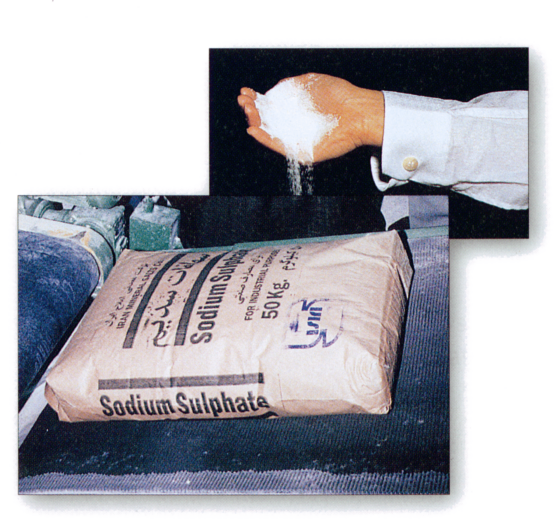

- Separating, drying, and packaging of sodium sulfate

- Due to the high economic efficiency of the plant and the customer’s satisfaction with the quality and robustness of the plant after more than 10 years of operation, the customer ordered two more identical plants.

Technical Data of the Plant

- Feed rate of solution: 52 m³/h

- Main components of solution: Na₂SO₄, NaCl

- Water evaporation: 4.5 t/h

- Product: Na₂SO₄

- Production rate: 6,7 t/h

Scope of Supply

EBNER’s scope of supply with company personnel included, among others:

- Basic and detailed engineering incl. design of main components

- Manufacturing of main components

- Supervision of the erection of the entire plant

- Supervision of the commissioning of the entire plant

EBNER – your competent partner in plant engineering

Due to many years of experience in a wide variety of industries and with a wide variety of solutions, EBNER is your contact to optimally carry out the process design, planning, delivery and assembly according to your needs.

Other References